overview

Posco DX Indonesia make steel manufacturing more competitive, capable of integrating IT and engineering

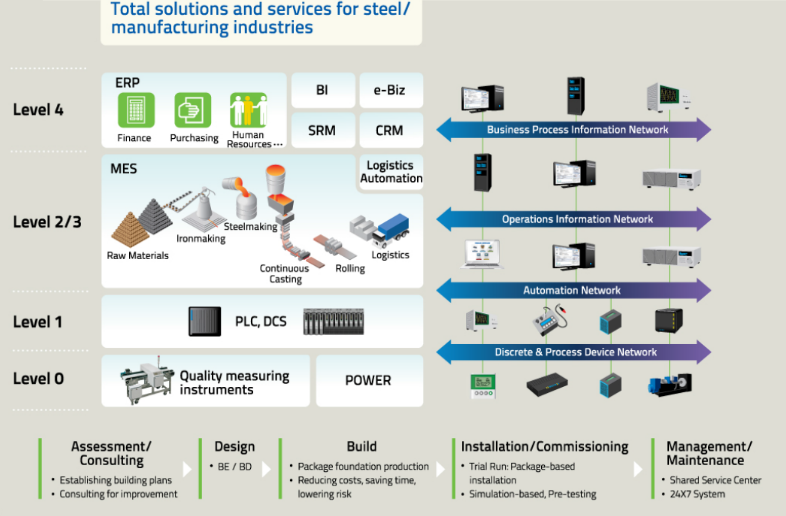

Posco DX Indonesia has been providing PT. Krakatau Posco, steel maker in Indonesia with integrated services-design, deployment and management of information systems and manufacturing process automation. Based on Posco DX's own one stop service expertise, we offer integrated solutions for diverse manufacturing industries.

OUR SERVICES

Facility Control

Facility Control part is the part for maintenance and repair to the electrical control and instrumentation systems in PT. Krakatau Posco's facilities.

Central Maintenance

Central Maintenance is part that provide the repair and maintenance Instrument & electric and also perform the process control system in a special section, this business part handles a section process that associated with the production.

Business Process & Computer

Business Process Computer is the business part that providing sevices that relate with Production Operation & Business System such as ERP, SCM, MES, Process Computer (HMI), and IT Infrasctructures as well as Networking, Telecommunication, Software, Hardware etc which are to support Manufacturing Production process.

Why Posco DX Indonesia ?

POSCO's Best Practice-based

Integrated steel mill process are big and complex system operation that require 24x7 non-stop runs. Posco DX Indonesia offer your company optimal services based on our extensive experience and knowledge accumulated over multiple decades through providing ITO and automation service to POSCO.

Higher efficiency trough Level 2-3 integration

System duplication is minimized through the integration of business computer (Level 3) and process computer (Level 2). This reduces costs and saves time involved in production and management, and also improves stability.

Global monitoring and response system

The global monitoring and response system is built to diagnose and take the necessary measures in overseas production centers with remote access and control. Standard model-based rollout guarantees quality consistency across global operations.